Automate Maintenance. Prevent Downtime.

QT9’s Preventive Maintenance software helps you schedule, track and optimize equipment upkeep—ensuring compliance and maximizing uptime.

Prevent Equipment Failures

Schedule maintenance before breakdowns to avoid downtime.

Extend Asset Lifespan

Keep machines running longer with consistent preventive care.

Reduce Emergency Repairs

Reduce costly last-minute fixes with automated upkeep.

Improve Compliance

Stay inspection-ready with timestamped maintenance logs.

Streamline Work Orders

Automate tasks and assign them based on asset or location.

Lower Operating Costs

Reduce repair bills and productivity loss with proactive service.

What is preventive maintenance software?

Preventive maintenance software helps organizations plan, schedule and track routine maintenance tasks to avoid equipment failures and extend asset life. It’s a key part of quality and operational standards such as ISO 9001, GMP and FDA regulations, supporting safer, more reliable performance and reducing unplanned downtime.

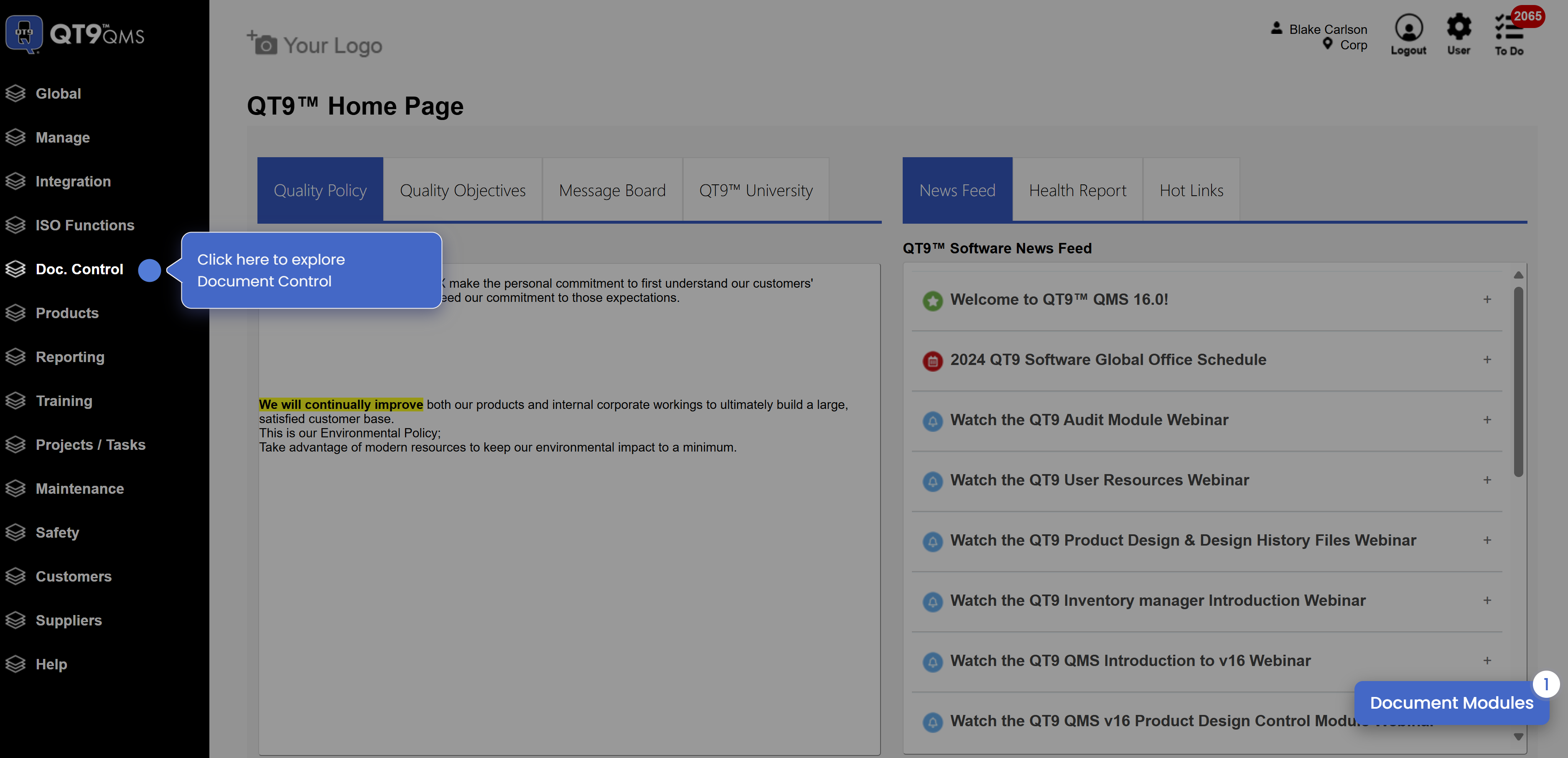

QT9’s Preventive Maintenance software automates work orders, reminders and checklists for all critical assets. The application centralizes maintenance records, supports compliance audits and streamlines communication between teams, all in a cloud-based, easy-to-use platform.

Interactive Video Demo

QT9 QMS Preventive Maintenance

What is preventive maintenance software?

Preventive maintenance software helps organizations plan, schedule and track routine maintenance tasks to avoid equipment failures and extend asset life. It’s a key part of quality and operational standards such as ISO 9001, GMP and FDA regulations, supporting safer, more reliable performance and reducing unplanned downtime.

QT9’s Preventive Maintenance software automates work orders, reminders and checklists for all critical assets. The application centralizes maintenance records, supports compliance audits and streamlines communication between teams, all in a cloud-based, easy-to-use platform.

All-in-one solution for better preventive maintenance records

Free up time with preventive maintenance tools built in to QT9 QMS.

Automated Schedules

Easily set up your preventive maintenance schedule for all equipment.

Email Alerts

Send maintenance alerts and reminders based on your settings.

Real-Time Reporting

Trend your maintenance work by meta data that you control.

Go Paperless

Auto-generate and assign work orders to specific users for frequent maintenance activities.

Track Labor Costs

Track materials and labor costs, plus total expenses for equipment upkeep.

Equipment Tracking

Track purchase and warranty dates, manufacturer and vendor.

To-Do Lists

Assign work orders to users to show on their system to-do lists.

Attach Related Files

Attach unlimited files to work orders and equipment.

Maintenance Activities

Assign multiple parts and materials with associated costs to maintenance activities.

Celebrated by Experts. Loved by Customers.

QT9 QMS is a leader in Preventive Maintenance Software on Capterra and Software Advice.

Get end-to-end quality management

FAQ: Preventive Maintenance

Preventive maintenance involves performing regular, consistent maintenance on equipment so that it is performing optimally. It involves tasks such as routine inspections, regular cleaning and part replacement. The goals of preventive maintenance are to mitigate the possibility of unexpected failure, extend the equipment’s lifespan and maximize operational efficiency.

Preventive maintenance is important in manufacturing and quality management as equipment failures can have detrimental effects on production timelines, triggering quality events that require extra attention and sap productivity. Practicing preventive maintenance keeps your organization running efficiently, maintains safety, extends the life of your equipment and ensures any warranties remain valid.

Automating preventive maintenance simplifies the entire equipment maintenance process -- scheduling maintenance, alerting you when maintenance is required, documenting results and tracking completion. Some of the key benefits of automating preventive maintenance include:

- Process efficiencies

- Software integrations

- Equipment data capture for reports and analysis

- Reduced operational costs

- Extend life of equipment

- Accident and injury prevention

- Ensure warranty coverage

QT9 QMS offers a preventive maintenance solution that allows you to easily create a maintenance schedule for all of your equipment and assign to users. Automated email alerts and reminders will ensure that maintenance tasks stay on track.

QT9 QMS includes more than 25 standard modules that connect to provide simplified quality management end-to-end. QT9’s QMS software is a highly rated, affordable, easy-to-use quality management system that excels at all of the processes that go into providing high-quality goods and services that are FDA and ISO compliant.

With QT9 QMS you get unlimited scalability and traceability at a great price, so you can bring quality products and services to market in the most efficient way.

Quality management resources

Best Software for Inventory Management in Regulated Manufacturing

Production Scheduling Software to Reduce Manufacturing Downtime

Optimize Manufacturing with In-Process Inspections

FDA QMSR Part 2: Preparing for FDA Inspections

QT9 QMS Earns 2026 Top Honors from Capterra and Software Advice

FDA QMSR Compliance Calls for a New Mindset

Try QT9 for free

Ready to simplify your quality processes? No credit card needed.