QMS Software Aerospace Aerospace QMS Software

Aerospace Quality Management Software (AS9100-Ready)

In today’s aerospace environment — whether you’re a tier-1 supplier or a specialty parts manufacturer, quality and compliance aren’t just boxes to check. You’re expected to prove compliance every time your customer, regulatory body, or lead contractor shows up for an audit. AS9100 is the globally accepted quality standard for aviation, space and defense organizations, and it’s built on ISO 9001 with aerospace-specific requirements added on.

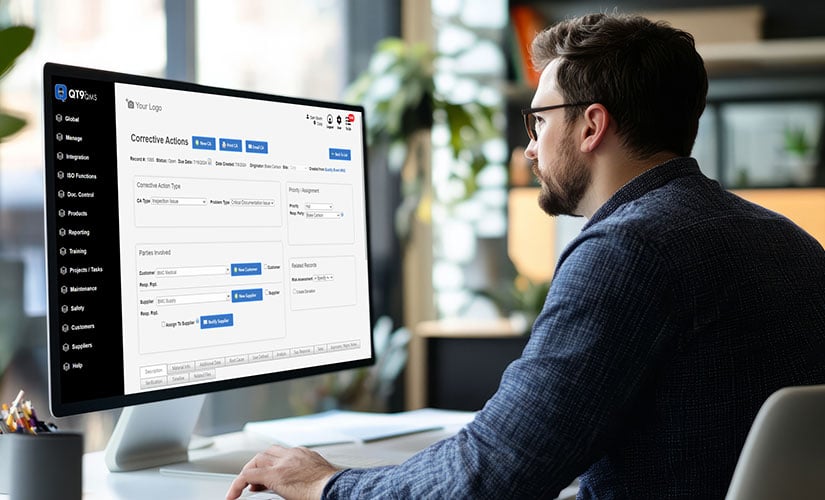

QT9 QMS centralizes everything you need to manage quality across your operation. From document control and audits to supplier quality and corrective actions, in a single, traceable system built for AS9100 compliance.

Why Aerospace Companies Choose QT9 QMS

Reduce Audit Stress

Instead of digging through spreadsheets and shared drives, all of your audit records live in one connected system. Document histories, approvals, training acknowledgments, and CAPA records are already organized and ready to present, with full review history built directly into the platform.

Connect Quality Data

Quality data shouldn’t live in isolation. QT9 links nonconformances, serial numbers, AS9100 clauses, and audit evidence automatically, so your team doesn’t have to manually piece together information. The result is fewer admin hours spent reconciling records and more time focused on improving quality.

Stay Ahead of Supplier Risk

Supplier information often ends up scattered across emails, spreadsheets, and shared folders. QT9 brings certifications, audit results, performance history, and delivery expectations into a single view. With supplier scorecards, document portals, and proactive alerts, potential issues are identified early, before they turn into costly nonconformances.

Features Aerospace Teams Rely On

Below are the most impactful capabilities that help aerospace companies stay compliant, efficient, and audit-ready:

-

Centralized Document Control

Maintain revision histories, electronic signatures, and controlled approvals in one secure repository. -

Risk & CAPA Management

Identify patterns early and drive corrective & preventive actions to closure with automated workflows. -

Supplier Quality Management

Evaluate, score, and monitor supplier performance — plus connect supplier issues to quality records. -

Audit & Training Management

Plan internal and external audits and assign training with reminders and completion tracking. -

Real-Time Analytics & Dashboards

Get visibility into quality performance across plants, product lines, and compliance KPIs.

End-to-end quality automation for aerospace and defense companies

- Built-in compliance tracking and reporting

- Document management with version control, revision history and electronic signature approvals

- Real-time data and analytics to identify, assess and mitigate risk throughout product lifecycle

- Automated workflows for reporting, investigating and resolving nonconformances

- Integrated supplier performance and compliance tasks

- Intuitive interface makes quality management accessible and actionable for everyone

QT9 QMS features for aerospace and defense

CAPA Management

Streamline corrective and preventive actions with automated workflows.

Employee Training

Assign and verify training with electronic tracking and reminders.

Achieve global aerospace compliance with AS9100-ready QMS

- Automate AS9100 document control and audits

- Standardize processes across global sites

- Link training, risk and CAPA to AS9100 clauses.

Control engineering and process changes across every project

- Track Engineering and revision changes

- Maintain traceability from design to release

- Capture approvals with eSignatures

- Prevent configuration mix-ups and rework

Link quality records directly to production and work orders

- Connect inspections to serial or lot numbers

- Capture calibration and test records

- Monitor real-time shop floor quality data

- Ensure traceability to each delivered unit

Monitor supplier quality across the entire supply chain

- Rate suppliers by quality and delivery scores

- Automate supplier corrective action

- Audit sub-tier supplier electronically

- Maintain continuous supplier approval status

Maintain required aerospace training and certifications

- Link training to AS9100 roles and processes

- Automate renewal alerts for certifications

- Verify employee competency by task

- Store audit-ready qualification records

Deployment options that fit your business

Every organization has different IT requirements. QT9 meets you where you are.

How QT9 QMS Helps Aerospace Organizations Solve Their Toughest Quality Challenges

How can QT9 help my aerospace company comply with AS9100 and other aerospace standards?

Aerospace manufacturers and suppliers must comply with rigorous standards like AS9100, which require documented processes, traceability, and evidence of effective quality controls. QT9 QMS centralizes your compliance documentation, automates version control, and enforces electronic signatures, helping you maintain alignment with AS9100 requirements. Built-in workflows guide reviews and approvals so you can demonstrate control over documents, processes, and records during internal and external audits without scrambling for files.

What common quality challenges do aerospace suppliers face and how does QT9 address them?

Aerospace suppliers often struggle with inconsistent processes, siloed data, and manual quality checks that are prone to error. QT9 QMS helps by:

-

Connecting quality records like CAPA, nonconformances, and audit findings in one platform so teams no longer waste time reconciling spreadsheets.

-

Automating notifications and escalation rules so issues are addressed quickly and consistently.

-

Providing configurable dashboards so quality leaders can instantly see trends and drive corrective action before small problems escalate.

How does QT9 make internal and external audits easier?

Auditors look for evidence: documented procedures, revision history, audit trails and corrective actions. QT9 QMS automatically logs every change, approval and review. With time-stamped electronic signatures that comply with regulatory requirements. This means your team spends less time preparing binders and more time focusing on quality improvement. Plus, real-time dashboards help you pull up key metrics instantly when an auditor asks for proof of compliance.

Can QT9 support supplier quality management for aerospace OEMs and sub-tier suppliers?

Yes. Supplier quality is mission-critical in aerospace, where defects can have serious consequences. QT9 enables you to:

-

Evaluate and qualify suppliers with consistent assessments.

-

Track supplier performance metrics over time.

-

Automatically trigger corrective actions when supplier issues are detected.

By giving you visibility into supplier performance and audit history, QT9 helps reduce risk across your supply chain and reinforces accountability.

How does QT9 help my team reduce manual processes and errors?

How does QT9 support continuous improvement at aerospace companies?

Continuous improvement is at the heart of quality standards like AS9100. QT9 empowers teams to identify trends with interactive dashboards, prioritize corrective actions based on real data and measure the effectiveness of improvements over time. By capturing root-cause analysis details and tracking CAPA effectiveness, your organization builds a stronger quality culture and drives measurable performance gains.

Why aerospace leaders choose QT9 QMS

Once expanded to using other modules we were impressed especially since it streamlined the Quality Admin process. Requires very little training to learn.

Capterra - Mid-Market (51-200 emp.)

We have been using QT9 for 8 years. It is a great tool for Quality. It is organized, professional and easy to use. QT9 helps tremendously with 3rd party audits. Audits go much faster and smoother with rapid record retrieval.

Mid-Market (51-1,000 emp.)

All the other systems I looked at were only bits and pieces of what I needed. QT9 had everything I needed to support my AS9100/ IS 9000 requirements.

Capterra - Mid-Market (51-200 emp.)

QT9™ QMS is flexible for your business.

QT9 lets you choose modules based on what's best for your organization.

Modules for any business size

With multiple modules to choose from, there's solutions for nearly anyone.

A solution that scales with you

Whether you are a large corporation or a small start-up you can use as many modules as you want.

Cross-Platform Support

Whether you use Android, iOS or Windows, QT9 works from virtually any web browser.

FAQ: Aerospace QMS Software

QT9 QMS is designed to help aerospace companies streamline compliance with AS9100, ISO 9001 and other aerospace regulations. QT9 offers on-premise or cloud-based platform options for centralized quality processes, documentation and traceability in one secure system. With automated workflows, integrated audit management and built-in document control, aerospace companies can maintain consistent quality standards and reduce administrative burden.

Yes. QT9 QMS supports AS9100 compliance through automated document control, nonconformance management, CAPA tracking, internal audits, training management and many other integrated applications. Each module is built to align with aerospace requirements for traceability, configuration control and continuous improvement.

QT9 QMS connects all quality processes in real time, linking nonconformances, corrective actions, supplier records and inspections to specific parts, lots or serial numbers. This complete traceability supports compliance reporting and helps aerospace manufacturers quickly respond to customer or regulatory audits.

Yes. QT9 QMS seamlessly integrates with QT9 ERP as well as other ERP solutions, unifying quality and production data. This integration enables automatic updates between quality events, production and inventory, reducing data entry and ensuring accuracy across the enterprise.

Aerospace companies can evaluate, approve, monitor and communicate with suppliers all within QT9 QMS. The system tracks supplier performance, manages incoming inspections and links supplier records to nonconformances and CAPAs. This ensures full visibility into supplier quality and helps meet AS9100 supply chain requirements.

QT9 QMS supports organizations of all sizes, from small aerospace parts suppliers to global OEMs. The modular design allows companies to scale their quality system as operations expand, while maintaining compliance with industry standards.

The aerospace and defense industries demand QMS platforms that comply with AS9100, ISO 9001, ITAR and other stringent regulations. QT9 QMS, ETQ Reliance, and MasterControl are widely trusted for supporting defense contractors and aerospace suppliers.

QT9 QMS is loved by aerospace manufacturers for many reasons, including:

- Automation for AS9100/IA9100 standards

- Closed-loop nonconformance with single-page reports

- On-premise or cloud deployment options

- Automated document control with compliant electronic approvals

- Supplier, customer and employee portals

- Real-time data and reporting availability

- Straightforward usability and award-winning customer support

AS9100 isn’t a legal requirement, but most prime contractors and aerospace OEMs won’t work with you unless you can demonstrate compliance to AS9100 and its traceability principles. It’s essentially assumed quality assurance in the aerospace supply chain.

Think of QT9 as your quality memory: it keeps records of what was done, when, and by whom. During an audit, you can show linked evidence, from training acknowledgements to CAPA closure and document approvals, without digging through shared drives.

Yes. QT9 not only stores supplier certification and performance data, but it also ties issues like late deliveries or nonconformances directly to supplier history. This allows you to make decisions based on performance trends, not guesswork.

Absolutely. QT9 centralizes quality records and workflows so teams in different locations are all working off the same system. No more siloed spreadsheets or inconsistent procedures.

Spreadsheets and emails don’t link quality data, meaning you spend time recreating context instead of solving quality problems. QT9 connects data across quality processes, saving time and reducing human error.

Resources for the aerospace industry

Top 5 eQMS Solutions for Medical Devices Manufacturers in 2026

Cannabis Industry Quality Management for Compliance, Consistency & Growth

Top 10 QMS Systems for 2026: A Buyers Guide

Ready to Move Forward?

Whether you’re early in your AS9100 journey or seeking to replace fragmented systems, QT9 QMS provides a connected, audit-ready quality platform built to scale with global aerospace operations.